Our technology

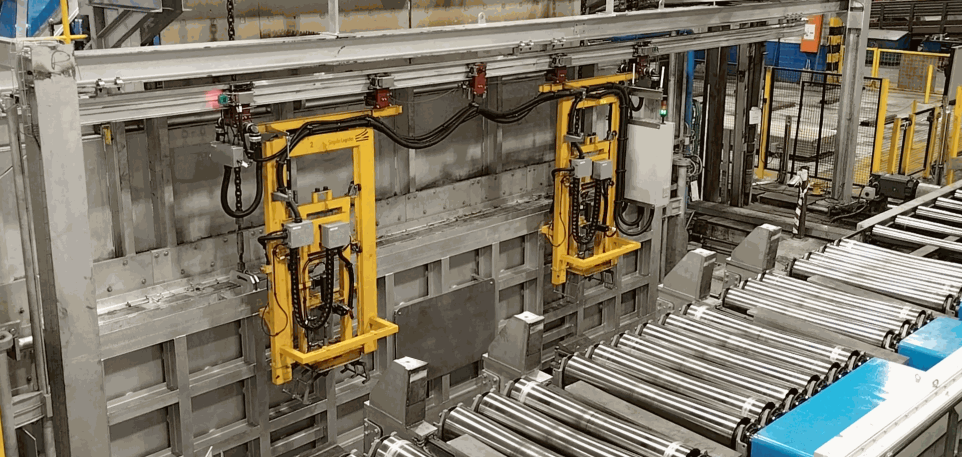

FLEXITRACK system

Implementing the Flexitrack system from Singular Logistics not only improves productivity and reduces costs, but also offers flexibility, autonomy, and sustainability. These benefits allow for the optimization of internal logistics operations, quickly adapting to the changing demands of the market while maintaining high standards of efficiency and quality.

Optimizes and increases space

Since the entire circuit is carried out overhead, at the optimal height for each installation, it frees up square meters of floor space and gains cubic meters in height

Minimal maintenance

Having good speed and efficiency ensures that tasks are completed quickly and that resources are used optimally to improve productivity and satisfaction.

Efficiency and productivity

Our trolleys move independently, following optimal routes, taking shortcuts and detours to achieve high and uninterrupted flows. The trolley itself makes the turns or changes, not the track, streamlining and optimizing travel times.

Available 24/7

Our system is available 24 hours a day, 7 days a week, 365 days a year, without the need to stop for charging, as it is permanently powered and supplied with 48V DC, also increasing safety for the operator.

High-quality installation at a reduced cost

The high-quality installation at a reduced cost is achieved through the use of standard IPE profiles with few moving parts and the elimination of the need for centralized control systems. This significantly reduces operational and maintenance costs.

Adaptability to complex situations

Ideal for transportation in hazardous areas, operating in a temperature range from -30°C to +50°C. It can transport high-temperature goods and is adaptable for crossdocking and loads of up to 1500 kilos or more, even for bulky items such as industrial doors and HVAC equipment.

How is the process?

The Flexitrack software is designed to give the trolleys autonomous control of their movement and operation without the intervention of a central system for guidance. The system ensures efficient transport through a well-defined process consisting of three stages:

1

The assignment

The Gateway (management software and auction or assignment of transport orders to be carried out) identifies the trolley with the shortest arrival time to the transport origin and assigns the request to it.

2

Movement to the origin

The trolley moves to the origin, requests loading permission, and once loaded, calculates the best route to the destination.

3

Optimal path

The route is calculated based on the maximum speed of each section, the allowed sections, and the maintenance and traffic conditions.

Discover our models

The perfect solution to optimize logistics

SL-100 Front loading

SL-100 Side-Loading

SL-1500 Standard