SL-100

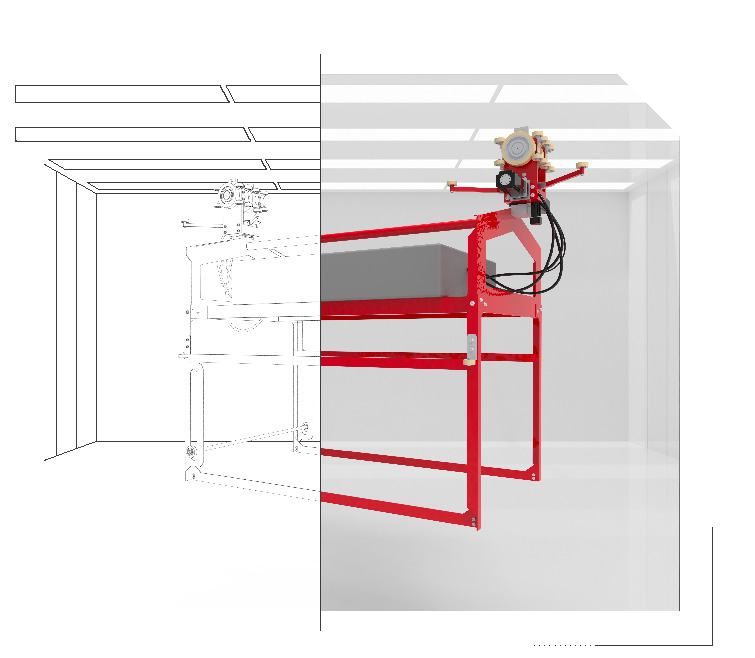

Side-loading Model

DESCRIPTION AND MAINTENANCE

Singular Logistics’ load transport system is built around an electrified overhead rail and independent carts equipped with artificial intelligence. Thanks to this onboard intelligence, each cart carries a complete map of the circuit and can communicate with the rest of the fleet, enabling it to find the fastest and most efficient routes based on task requests and current traffic conditions. Shifting the intelligence from the system to the carts not only simplifies configuration eliminating the need for any programming but also delivers significant savings in infrastructure costs.

Instead of using expensive materials like aluminium, the rails are built from standard steel IPE profiles, which are far more cost-effective. What is more, components like rail switches—traditionally one of the main maintenance hotspots—are eliminated entirely.

In short, Singular Logistics’ disruptive system offers the same capabilities as a traditional electrified rail system, but at a much lower cost, with reduced maintenance needs, simpler installation, and greater flexibility and scalability. This system brings competitive advantages to small and medium-sized enterprises that were previously only available to large production centres.

At Singular Logistics, we have developed an innovative and fully autonomous intralogistics solution. Our system is built around an advanced electrified rail with independent carts equipped with state-of-the-art artificial intelligence. This technology gives each cart a comprehensive view of the circuit, allowing it to optimize its routes while constantly communicating with other carts to ensure the best path in real time.

Thanks to their self-management capabilities, our carts analyse factors such as incoming task requests and current traffic conditions across the system, always selecting the fastest and most efficient routes. This intelligent autonomy eliminates the need for manual programming, greatly simplifying system configuration and reducing infrastructure costs.

With Singular Logistics, you don’t just automate your processes—you take a decisive step towards Industry 4.0, where efficiency, technological innovation, and cost savings are key to staying competitive.

In its standard version, the SL100 incorporates a conveyor belt or powered rollers to automate the loading and unloading of Eurobox containers in various sizes.

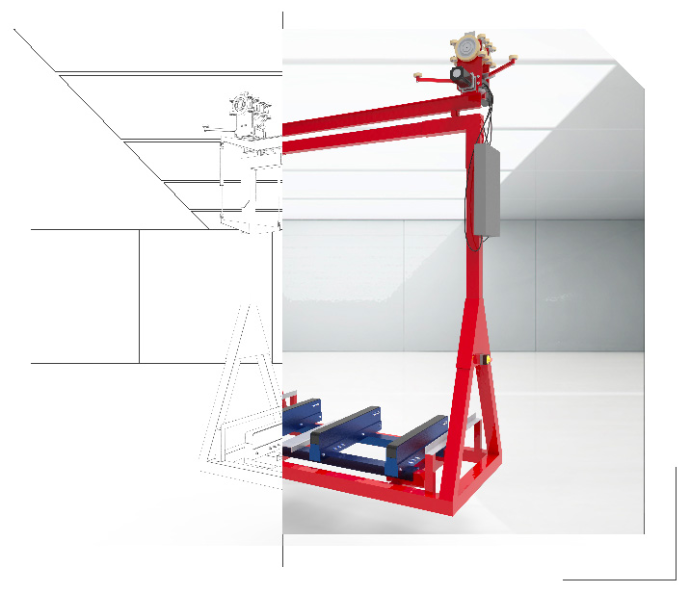

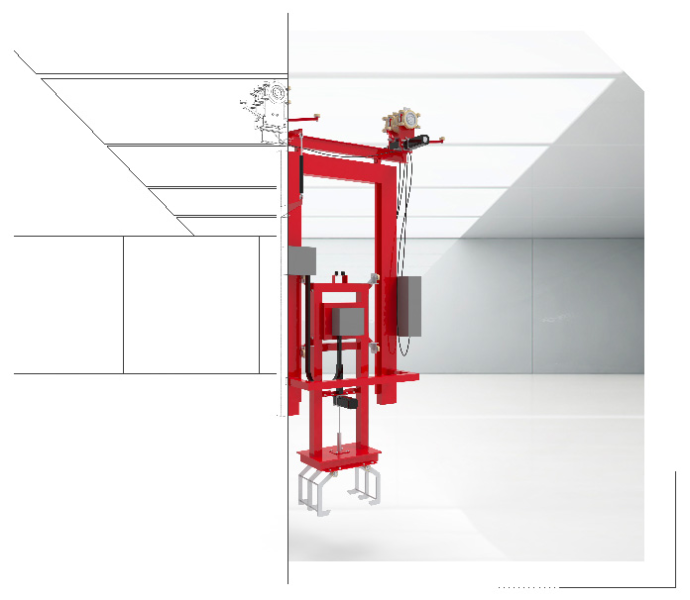

It is designed as suspended transport. By installing the rail above the production area, the structure of the ceiling trusses is typically used to support the rail. This way, the floor space previously dedicated to transport is freed up and can be repurposed for productive use. To lift the boxes or materials to the rail height, an elevator is provided.

TECHNICAL & ELECTRICAL DATA

TECHNICAL & ELECTRICAL DATA

SL-100. LIGHTWEIGHT TRANSPORT SYSTEM

The SL-100 is Singular Logistics’ solution specifically designed for the transport of lightweight loads, with a maximum capacity of 100 kg in Eurobox containers, although it also offers the option to add a loading accessory (Hook). The main advantage of this type of overhead transport system is the ability to free up floor space in the production area for other activities, making it ideal for both retrofitting into existing facilities that cannot accommodate a traditional system, as well as for sectors that require a high level of hygiene and cleanliness—since the equipment can operate at all times without interrupting production.

To lift the boxes or goods to the rail height, a lift designed specifically for this purpose is available.

Other products

You might be interested

Request information about

SL-100 Side-loading

Other products

You might be interested